Custom cable assemblies are essential components across various industries, including automotive, aerospace, telecommunications, and medical devices. This comprehensive guide will explore everything you need to know about custom cable assemblies, from their components and design process to applications and benefits.

What is a Custom Cable Assembly?

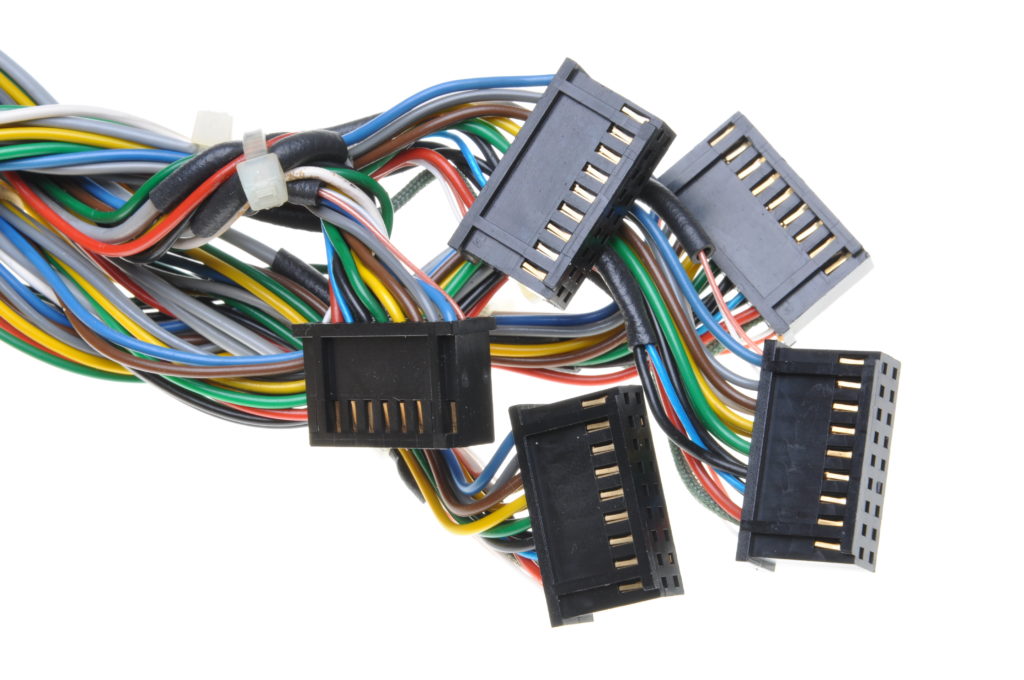

A custom cable assembly is a bundle of cables or wires that are combined into a single unit with connectors and terminations tailored to specific applications. These assemblies are designed to meet unique operational requirements, ensuring reliability and efficiency in different environments.

About Darlox (Zhijian) Custom Cable Assembly

Darlox (Zhijian) is a leading manufacturer specializing in custom cable assemblies for a variety of industries. With years of experience and a commitment to quality, Darlox provides tailored solutions that meet the unique needs of its clients. Their expertise spans across sectors such as automotive, medical devices, telecommunications, and industrial automation.

Key Offerings by Darlox (Zhijian)

- Custom Design Services: Darlox works closely with clients to develop cable assemblies that meet exact specifications.

- High-Quality Materials: The company uses premium materials to ensure durability, reliability, and compliance with industry standards.

- Comprehensive Testing: All assemblies undergo rigorous testing to guarantee performance under various conditions.

- Global Supply Chain: With a strong supply chain network, Darlox ensures timely delivery and scalability for large projects.

Components of a Custom Cable Assembly

- Cables and Wires: The primary component, selected based on the required electrical and environmental specifications.

- Connectors: Ensure a secure and stable connection between devices.

- Shielding: Protects against electromagnetic interference (EMI).

- Jackets: The outer layer that protects the assembly from physical damage.

- Terminations: The points where the cables connect to a device or another cable.

Benefits of Custom Cable Assemblies

- Tailored Solutions: Designed to meet specific needs, ensuring compatibility and efficiency.

- Improved Performance: Custom assemblies are built to handle unique operational demands, enhancing performance.

- Durability: High-quality materials and precise engineering ensure longer service life.

- Space and Weight Optimization: Custom assemblies can be designed to minimize space usage and reduce weight.

Design Process of a Custom Cable Assembly

1. Needs Assessment

The first step is understanding the specific requirements of the application, including:

- Electrical specifications (voltage, current, signal type)

- Environmental conditions (temperature, moisture, vibration)

- Regulatory standards (UL, RoHS, etc.)

2. Material Selection

Choosing the right materials for cables, connectors, and shielding to ensure optimal performance and compliance with industry standards.

3. Prototyping

Creating a prototype to test the design, ensuring it meets all specifications before mass production.

4. Testing and Validation

Performing rigorous tests to ensure the assembly meets all functional, safety, and quality requirements.

5. Production

Once validated, the cable assembly moves into full-scale production.

Applications of Custom Cable Assemblies

Custom cable assemblies are used in a wide range of industries:

- Automotive: For advanced driver-assistance systems (ADAS), infotainment systems, and engine controls.

- Aerospace: For avionics, communication systems, and navigation.

- Medical Devices: For imaging equipment, diagnostic devices, and patient monitoring systems.

- Telecommunications: For network infrastructure, data centers, and fiber optics.

- Industrial Equipment: For robotics, automation systems, and heavy machinery.

Choosing the Right Cable Assembly Manufacturer

When selecting a manufacturer for your custom cable assembly, consider the following factors:

- Experience and Expertise: Ensure the manufacturer has experience in your industry.

- Certifications: Look for compliance with industry standards such as ISO, UL, and RoHS.

- Customization Options: Choose a manufacturer that offers a wide range of customization options.

- Quality Control: Ensure the manufacturer has a robust quality control process.

- Customer Support: Reliable customer support is essential for addressing any issues that may arise.

Future Trends in Custom Cable Assemblies

- Miniaturization: Demand for smaller and lighter assemblies is increasing, particularly in the medical and aerospace industries.

- Increased Data Transmission: The need for high-speed data transmission is driving innovations in cable assembly design.

- Sustainability: Eco-friendly materials and manufacturing processes are becoming more prevalent.

Conclusion

Custom cable assemblies are vital for ensuring efficient and reliable performance in various applications. By understanding the components, design process, and applications, businesses can make informed decisions when selecting the right custom cable assembly for their needs. Working with an experienced manufacturer, like Darlox (Zhijian), can further ensure the success and longevity of the assembly in any given application.

Comments are closed