In high-speed data transmission systems, maintaining signal integrity is paramount. One critical factor that can impact signal quality is impedance mismatch, which occurs when there’s a disparity between the impedance of the transmission line and the impedance of the connected components. Such mismatches can lead to reflections, signal loss, and distortion, making it difficult for the system to transmit data efficiently.

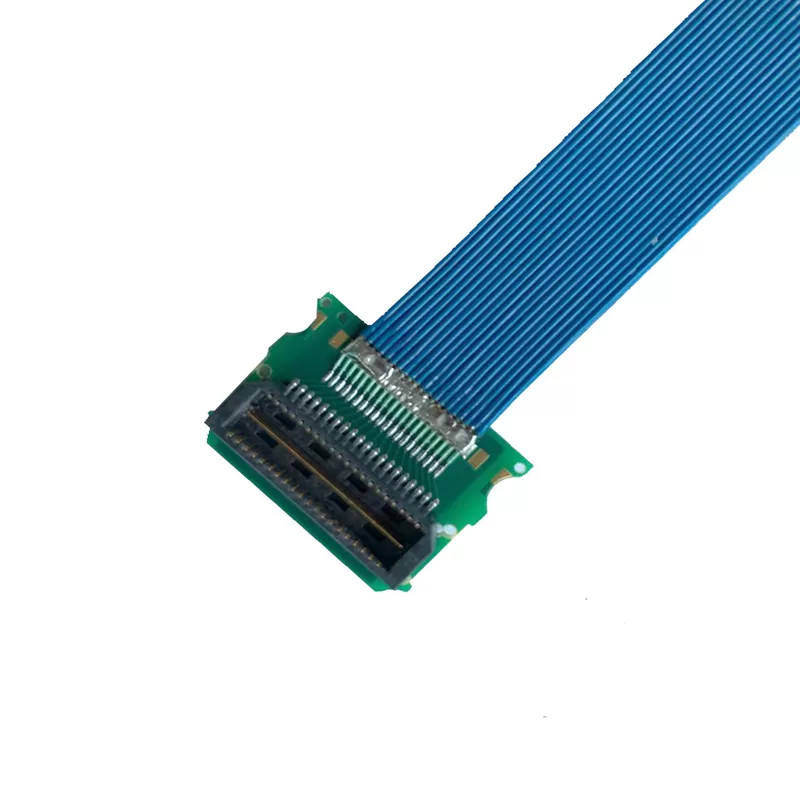

One effective way to address impedance inequalities in multi-conductor systems is by using MICTOR Multi-Conductor Cable Assemblies. These specialized cable assemblies are designed to mitigate impedance mismatches, ensuring consistent signal performance in high-speed applications. In this article, we’ll explore how MICTOR assemblies work to lessen impedance inequalities and why they are an essential component in modern electrical systems.

1. What is Impedance Mismatch and Why Does It Matter?

Impedance mismatch occurs when there is a difference between the impedance of the cable and the device it’s connected to, such as connectors, circuit boards, or other components. In high-speed data transmission, impedance is a key factor in ensuring that signals pass through the system without reflection or distortion. When impedance mismatches occur, signals can be reflected back toward the source, which causes energy loss and delays, leading to degraded signal quality and reduced system performance.

In multi-conductor systems, such as those found in LVDS (Low Voltage Differential Signaling) and MICTOR applications, maintaining consistent impedance across all conductors is essential to achieving high-speed and error-free data transmission. This is where MICTOR Multi-Conductor Assemblies shine.

2. How MICTOR Multi-Conductor Assemblies Reduce Impedance Inequalities

MICTOR assemblies are a type of high-performance multi-conductor cable designed specifically to address the issue of impedance mismatch. These cable assemblies use a combination of advanced engineering techniques to ensure that the impedance remains uniform across all conductors. Here’s how MICTOR assemblies help lessen impedance inequalities:

Precision Manufacturing and Materials

MICTOR assemblies are manufactured using precise processes that ensure the conductor spacing and insulation materials are optimized for consistent impedance across the entire assembly. This precise control of geometrical parameters minimizes variations in impedance, ensuring that signals flow smoothly through the cable with minimal reflections.

MICTOR cables typically use high-quality dielectric materials, which play a crucial role in maintaining the characteristic impedance (the impedance of the cable) at a constant value. Materials with stable dielectric properties reduce the likelihood of impedance variations across the length of the cable, leading to more predictable and reliable signal transmission.

Conductor Pairing and Shielding

MICTOR multi-conductor assemblies often feature closely paired conductors, where the differential pairs are arranged to reduce the risk of impedance mismatch. The conductors are carefully selected and positioned to ensure that each pair maintains a consistent impedance throughout its path. This careful conductor pairing helps reduce the possibility of signal degradation due to impedance variations.

In addition, many MICTOR assemblies incorporate high-quality shielding to further enhance signal integrity. Shielding reduces the effects of electromagnetic interference (EMI), which can contribute to impedance variations and signal loss. By preventing external noise from affecting the cable, the shield ensures that the signal remains clean and within the desired impedance range.

Balanced Design for Multi-Conductor Systems

The balanced design of MICTOR assemblies helps to maintain impedance matching across multiple conductors. When conductors are designed with a balanced layout—meaning that each conductor within the assembly is closely matched in terms of distance, insulation, and material properties—it helps to preserve the overall impedance balance. This is especially important in multi-conductor configurations, where the potential for impedance imbalances is higher due to the increased number of conductors.

3. Benefits of MICTOR Multi-Conductor Assemblies

Enhanced Signal Integrity

By addressing impedance mismatches, MICTOR multi-conductor assemblies ensure that high-speed signals pass through the system with minimal loss and reflection. This results in cleaner signals, better data integrity, and more reliable communication in systems that rely on high-speed data transmission, such as LVDS, eDP, display interfaces, and high-frequency analog systems.

Reduced Signal Reflection and Crosstalk

Signal reflection and crosstalk (interference between adjacent conductors) can severely degrade performance in multi-conductor systems. By minimizing impedance imbalances, MICTOR assemblies help reduce reflection, which in turn reduces the likelihood of signal crosstalk. This results in more stable and interference-free data transmission.

Higher Bandwidth and Speed

MICTOR cable assemblies are designed to handle high-frequency signals with minimal attenuation, making them suitable for high-bandwidth applications. With consistent impedance and improved signal integrity, these assemblies are ideal for use in systems that require fast data transmission, such as high-definition displays, networking equipment, medical imaging systems, and automotive electronics.

Longer System Lifespan

By preventing signal degradation and minimizing the risks associated with impedance mismatch, MICTOR assemblies can contribute to a longer lifespan for the entire system. Reliable signal transmission reduces wear and tear on components, preventing the need for frequent repairs or replacements, and ultimately reducing maintenance costs.

4. Applications of MICTOR Multi-Conductor Assemblies

MICTOR multi-conductor assemblies are commonly used in a wide variety of high-performance applications, including:

- Medical Devices: High-speed data transfer is critical in medical imaging equipment and diagnostic systems, where accurate signal transmission is vital for proper function.

- Automotive Systems: With the increasing demand for high-speed data transmission in advanced driver-assistance systems (ADAS) and infotainment systems, MICTOR assemblies provide the necessary reliability and performance.

- Telecommunications: In telecommunications networks, maintaining signal integrity is crucial for high-quality voice and data transmission. MICTOR assemblies ensure smooth communication by addressing impedance mismatch.

- Consumer Electronics: High-speed HDMI, DisplayPort, and USB interfaces rely on MICTOR assemblies to ensure seamless data flow and signal clarity.

- Industrial Control Systems: In automated systems, MICTOR multi-conductor assemblies help maintain reliable communication between sensors, controllers, and other devices.

5. Conclusion

MICTOR Multi-Conductor Assemblies play a crucial role in modern data transmission systems, where impedance mismatches can lead to significant signal degradation. By ensuring consistent impedance across all conductors, MICTOR assemblies help enhance signal integrity, reduce reflections and crosstalk, and support faster data rates. Whether used in medical devices, automotive electronics, or high-performance networking equipment, MICTOR assemblies are engineered to meet the highest standards of performance and reliability, providing a vital solution for high-speed, low-loss signal transmission.

By choosing MICTOR assemblies, you can ensure that your multi-conductor systems deliver superior performance, reduced signal degradation, and increased system lifespan, all while keeping pace with the demands of modern technology.

Comments are closed